Water impacts most every property of the green sand during both molding and casting. High or low moisture accounts for 90% of casting defects including blows, scabs, burn-on, metal penetration, pinholes, stickers, and inclusions.

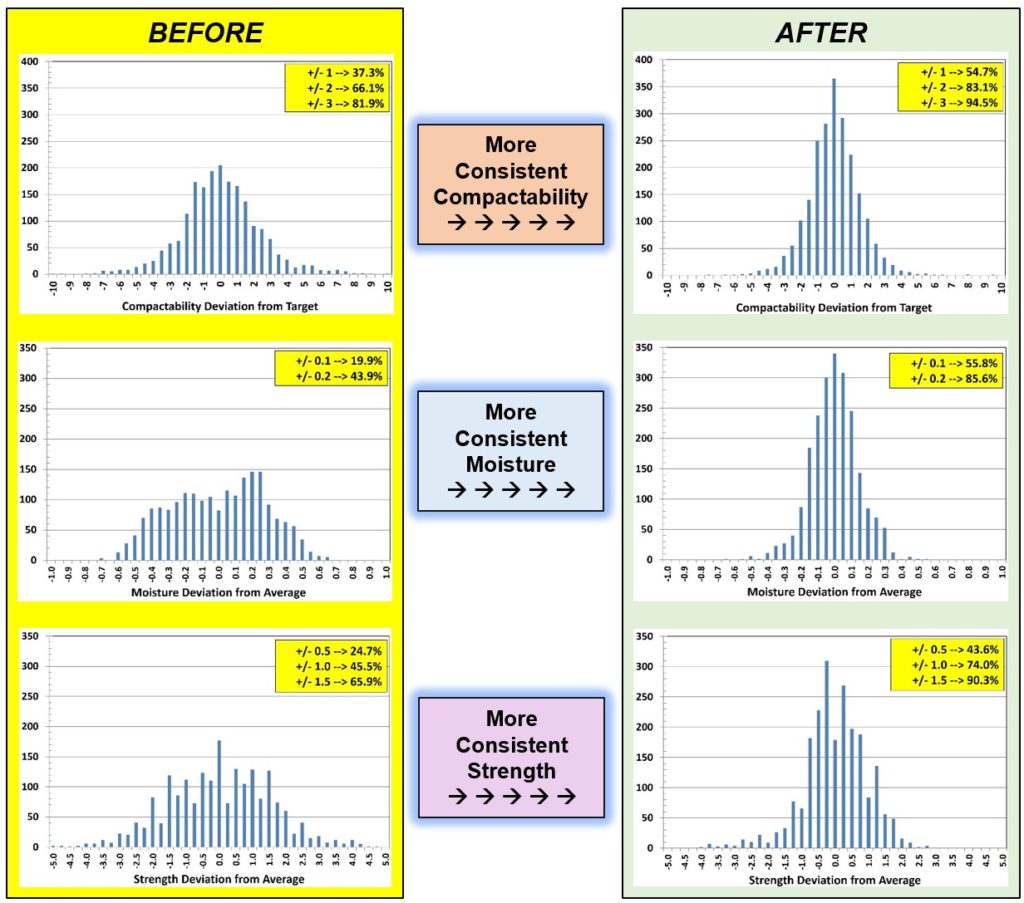

Furness-Newburge has developed an advanced method to improve foundry sand system control. The technology combines better moisture measurement with fundamental green sand science to improve the automatic addition of water and bond pre-mix to green sand systems. Using these improvements, foundries can decrease scrap by reducing the variability in compactability, moisture, and strength.

Even foundries with good compactability control do not necessarily have low strength or moisture variation. A system that improves adjustment of both bond pre-mix and water addition can reduce these variations and make better castings.

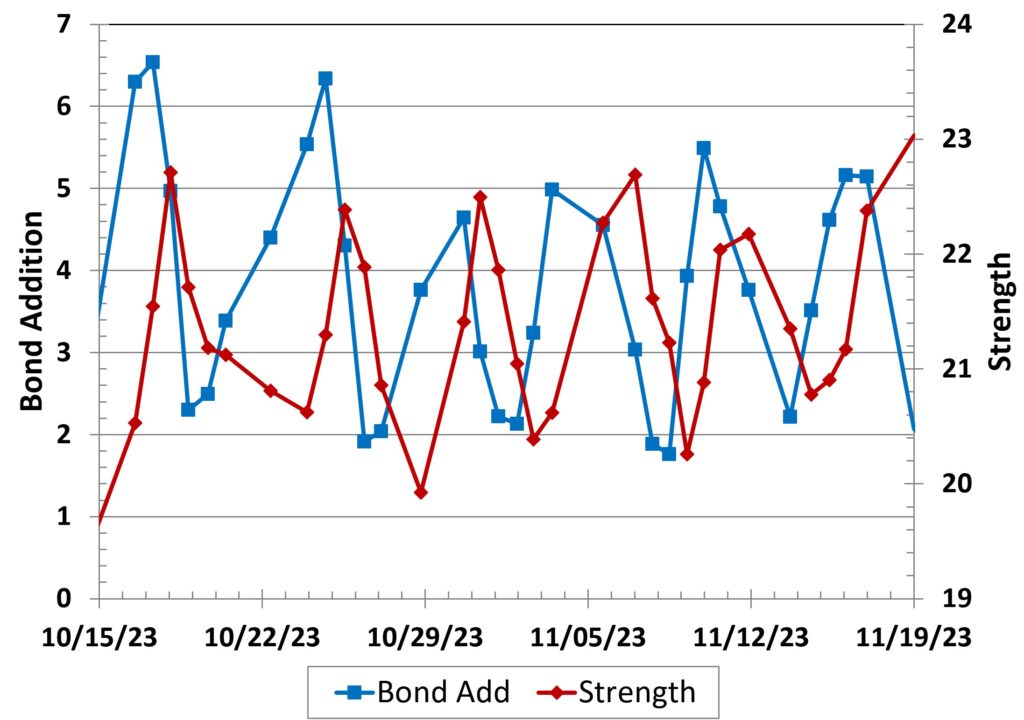

Below is an example of a system with good compactability control (75% +/-1, 92% +/-2, 98% +/- 3) using traditional control methods, but variable strength due to over-correction.