Sonoperoxone® System Users Reduce Environmental Impact

High production green sand foundries are under increasing pressure to reduce hazardous air pollutants (HAPs) and volatile organic compounds (VOCs) that are emitted during pouring, cooling and casting shakeout (PCS). Smoke and odor from PCS emissions are a serious concern in the workplace environment and a source of neighborhood complaints. The green sand’s coal and the core’s resin binder are the primary sources of organic HAP and VOC emissions. The pouring of high temperature molten metal into the sand mold causes the release of organic compounds from the coal and organic resins. These organic compounds are necessary to the casting process because they provide a reducing atmosphere at the casting surface which prevents casting defects and provides good surface finish.

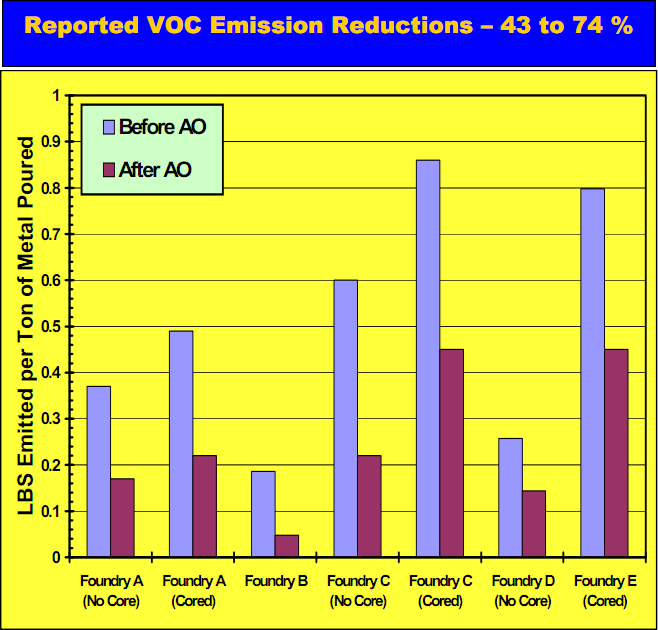

These organic compounds have three fates: they are incinerated from the heat of the molten metal as they escape the mold, they are adsorbed in the cooler sections of the mold, or they are released into the atmosphere. Most of these organic compounds belong to the benzene family (benzene, toluene, xylene) and are considered harmful air pollution. The Sonoperoxone® treatment system prevents pollution at its source by improving the ability of the sand mold to adsorb these organic compounds. the advanced oxidants clean out the pores of the coal and clay and increase the porosity of these green sand components (See graph [8]). Increasing the porosity of the sand mold allows the mold to retain more of the organic compounds. This results in lower emissions being released and more consumables being retained for the next casting cycle. Even some emissions from the chemically bonded cores are captured in the green sand mold. However, the emissions reduction decreases as core size increases because the process does not treat the core sand. Core sand emissions bypass the green sand mold.

Effect of advanced oxidation treatment of green sand: Pore volume increase from Glowacki et al [8].

Because bond costs money and bond usage

is reduced with Sonoperoxone® and Pneu-Col®

The advanced oxidants generated by the Sonoperoxone® process interact with the clay and coal in the bond to make them more efficient. Clay activation increases and coal usage drops. Sand strength per unit of clay increases. Foundries with Sonoperoxone® Blackwater systems have seen their bond consumptions drop by up to 40% by combining bag house dust recycle with advanced oxidant activation.

Sonoperoxone® systems make a foundry more competitive by simultaneously reducing bond consumption and pollution.