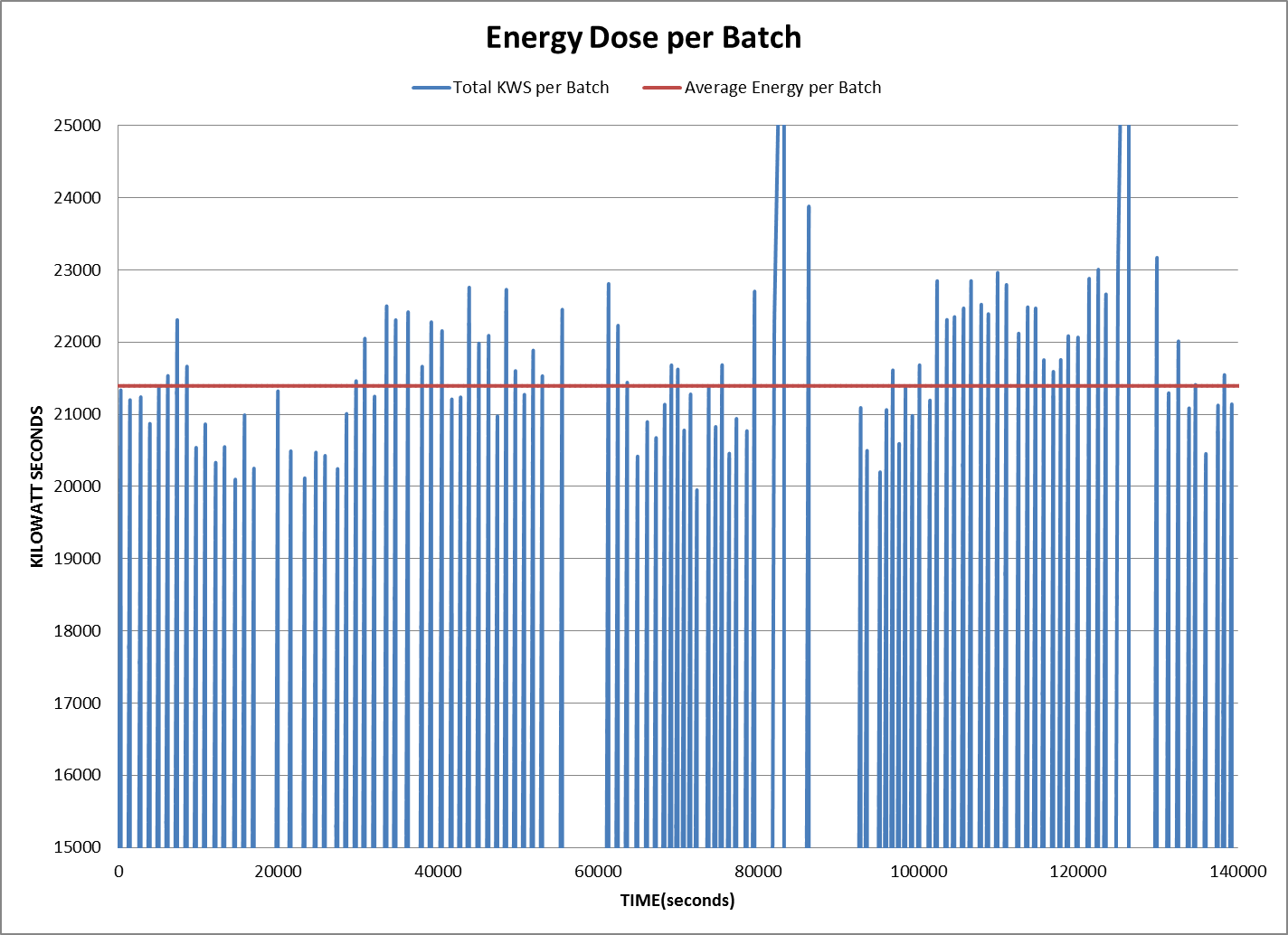

Mull to Energy (MTE) control systems automatically adjust the mulling time based on the sand strength development during a mulling cycle. Traditional batch mullers required set mixing times long enough to properly coat sand grains. While this approach is effective, it cannot accurately account for the changing conditions in the sand system such as core loading or sand to metal ratio changes and causes sand batches to be either over mulled (mulled past the clay’s temper point) or under mulled (not mulled long enough for clay to reach its peak strength). Over/under mulled batches contribute to inconsistent sand properties and can be found by tracking the energy dose added to each batch. The graph below is taken from a batch muller energy study and shows the variability of energy dose in each batch.

The graph demonstrates the energy dose (measured in KWS) can fluctuate wildly from batch to batch.

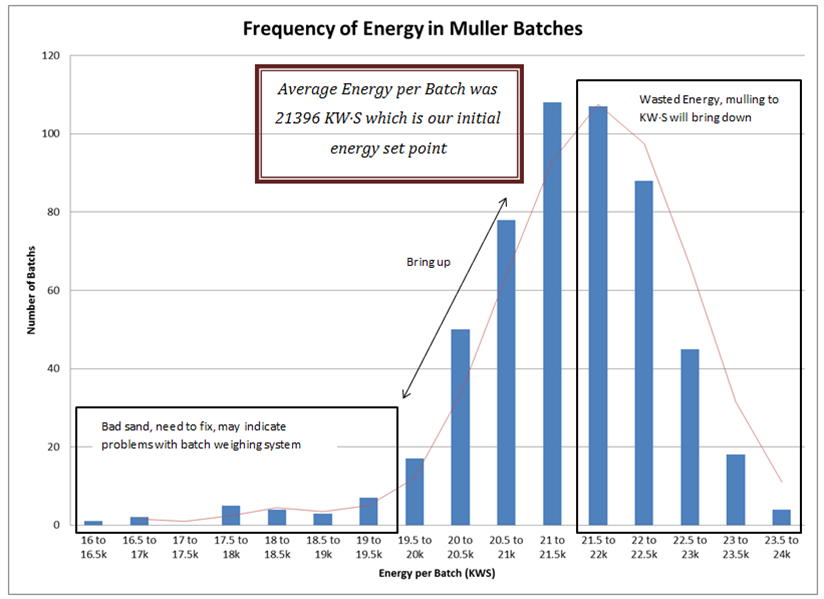

When tracked over a three day study, the muller shows even more variation. The graph below shows the quantity of batches with each energy dose over the three day study. Note that the graph shows both over mulled and under mulled batches.

Mull to energy stabilizes sand coming from the muller by controlling the energy dose per batch. This helps keep the sand properties consistent from batch to batch while lowering the energy bill for the muller. In most cases there was a reduction in utilization of the muller and some mullers had an increase in through put as well.

Mull to energy stabilizes sand coming from the muller by controlling the energy dose per batch. This helps keep the sand properties consistent from batch to batch while lowering the energy bill for the muller. In most cases there was a reduction in utilization of the muller and some mullers had an increase in through put as well.

To learn more about the benefits of mull to energy and how it can help your foundry contact us.